Introduction

Investment casting and die casting are the most widespread methods of producing complicated metal components in the metal manufacturing world. Both of them can be used to the same end, though they are quite different in terms of processes, material consumption, and cost efficiency. These differences are important for an engineer or manufacturer to select the appropriate approach to use in his or her project.

Then, what is the difference between investment casting and die casting? This paper is going to give you a clear idea of the highly significant differences between these two casting techniques. You will be in a position to make the appropriate choice for your manufacturing requirements by examining their processes, benefits, constraints, and best use.

What Is Investment Casting?

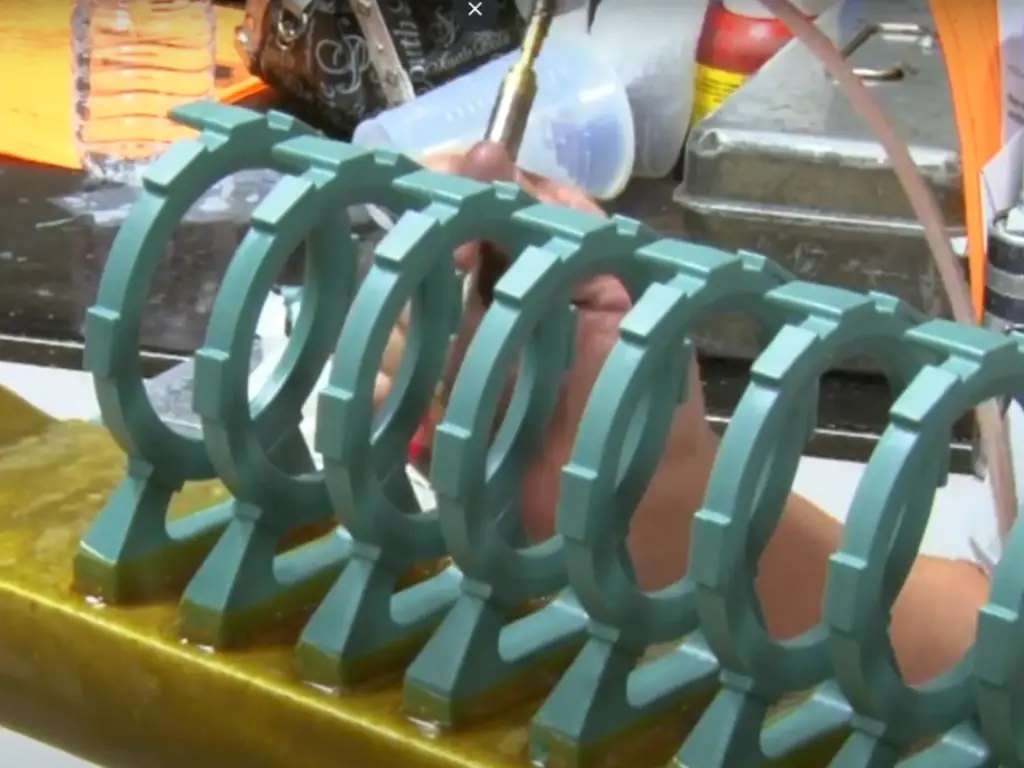

Investment casting, also called precision casting, is a procedure that involves a wax model and a coating of ceramic shell to create a mold. Once the mold is created, molten metal is then poured into it, filling the empty space that has been filled by the melted-away wax pattern. The process can also produce parts that are highly precise, making it the best option for applications where precise dimensions are crucial. It can create complex shapes that would be hard or impossible to produce using other metal casting processes.

Investment casting is a process that consists of a number of steps. To start with, a wax pattern is drawn in detail. After that, it is dipped several times into a ceramic slurry to take the shape of a mold. The wax is then heated out of the mold, and the ceramic is hardened. Molten metal is then added to the mold to form the cast part. This technique is ideal for meeting a project’s requirements where the final part must adhere to precise dimensions and complex geometries. It is commonly used for high-precision components made from metals such as stainless steel, titanium, or cobalt-chromium.

Investment casting has also developed in contemporary foundry in various special forms to satisfy various performance and cost considerations. The best of these is the silica sol investment casting which has a high level of surface quality, accuracy of dimension and is environmentally friendly.

Advantages & Limitations:

| Advantages | Limitations |

| High precision with tight tolerances (±0.1mm). | Slower production speed compared to die casting. |

| Ideal for complex geometries and parts requiring intricate details. | Higher per-unit cost for large-volume runs due to slower production rates. |

| Great for small batch production, offering flexibility for custom designs. | More expensive molds for small batch production. |

| Excellent surface finish, reducing the need for post-processing. |

What Is Die Casting?

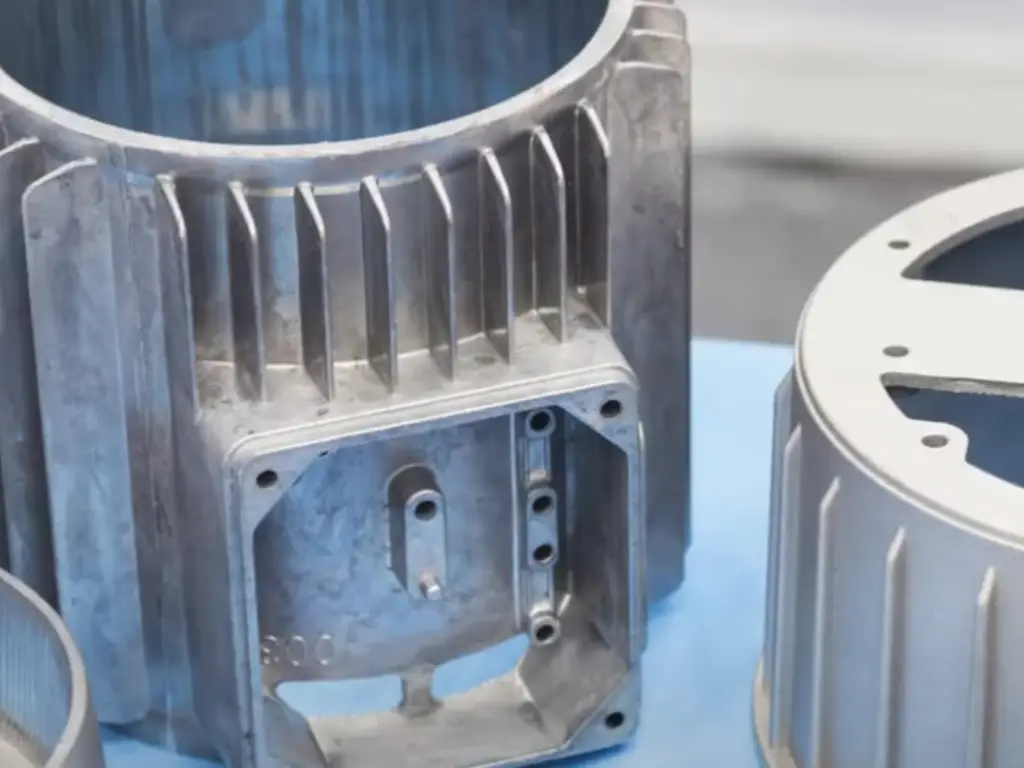

Die casting is the process that entails the injection of molten metal into a metal mold under high pressure. This is the best choice for manufacturing smooth-surface parts with a high level of accuracy in dimensions. Die casting, unlike investment casting, offers unique advantages in being very useful in the mass production of parts that need to be produced at high speed. It is an excellent option for different applications where large volumes of uniform parts are required.

The die casting process begins by preheating the mold, and then high-pressure molten metal is injected into the mold cavity. The final part is made by rapid cooling and solidification of the metal. Some of the popular materials used in die casting are aluminum, zinc, and magnesium alloys. Die casting is also optimal for parts that need high repeatability and excellent mechanical properties, making it the best choice for industries like automotive and electronics, where consistency and durability are crucial.

Advantages & Limitations:

| Advantages | Limitations |

| Fast production speed with high repeatability, ideal for large-volume production. | Limited material range, primarily uses non-ferrous metals like aluminum and zinc. |

| Low per-unit cost for large production runs. | High initial tooling cost, though molds last longer than investment casting molds. |

| Good surface finish, reducing the need for further post-processing. | Less flexibility for small batch production or very complex geometries. |

| Can produce larger components at a faster rate. |

Investment Casting vs Die Casting: A Detailed Comparison

In comparing investment casting and die casting, there are various critical aspects involved, which are the level of accuracy, selection of materials, cost of a mold, the rate of production, and surface finish. Such factors decide the appropriateness of every process to various manufacturing needs.

Precision

Investment casting is characterized by a very high level of precision and has a tolerance as narrow as ±0.1mm. This suits it well for industries in which very fine details and precise specifications are vital, e.g., aerospace and medical equipment. As a casting method, investment casting is often considered the better option when dealing with parts that require extremely tight tolerances and complex geometries. The investment casting process involves creating a wax pattern, coating it with a ceramic shell, and then melting out the wax to form a mold for pouring molten metal. The resulting investment cast parts are highly accurate, making it ideal for high-precision applications.

Die casting, on the other hand, is also very precise, but has a little lower tolerance at ±0.25mm. Although not as accurate as investment casting, it is nevertheless a better option for casting methods requiring high-speed production and large volumes of components. It offers good dimensional accuracy and is widely used in the mass production of components such as parts of automobiles.

Material Range

The range of materials available in investment casting is wide, which includes ferrous, stainless steel, titanium, and cobalt-chromium alloys. High strength and corrosion resistance applications of high strength have made these materials a popular choice.

On the contrary, aluminum, zinc, and magnesium alloys are mostly used in die casting, particularly in larger production runs, making die casting a suitable method for such applications. All these are non-ferrous metals, which are lightweight and possess good mechanical properties, but the variety of materials available is less than that of investment casting.

Mold Cost

Investment casting is relatively cheaper in mold cost, particularly in small to medium batch production. This is due to the fact that the mold is made by coating the wax model in ceramic which is cheaper as compared to steel molds of die casting.

Die castings molds, on the other hand, are made of steel and have high initial expenses. Although these molds cost more upfront, they have a potential to last longer and they are more appropriate for large volumes production, which makes them cost effective in the long run.

Production Speed

The time used in investment casting is more time consuming because of elaborate mould manufacturing and casting of metal. The lower speed has the advantage of being more appropriate with small batches or complex parts.

Die casting, on the contrary, has a higher speed of production; hence it is the best method to manufacture large quantities of components within a short period of time. Die casting is applied at high pressure to make sure that molds are filled within a short time and this makes the entire process of manufacturing to be fast.

Surface Finish

The two processes provide superb surface finishes, albeit the difference in the quality of the finish. Investment casting offers a very good surface finish particularly on complex components such that further post processing is not necessary.

Although die casting also gives a smooth finish, it normally takes fewer steps of finishing compared to other techniques but in some instance it does not give the same precision as investment casting.

Batch Size & Applications

Small batch production or complex parts such as aerospace, medical and military industries should be done using investment casting. The process is very effective in producing components that have complicated geometries and also components that are very small in size.

Die casting is better applied in large scale production of more basic parts needed in various industries such as auto manufacturing, electronics, and consumer appliances where time and quantity are more important.

| Comparison Aspect | Investment Casting | Die Casting |

| Precision | Extremely high (±0.1mm) | High (±0.25mm) |

| Material Range | Various steels, titanium alloys | Primarily aluminum, zinc, magnesium alloys |

| Mold Cost | Lower mold cost | Higher mold cost |

| Production Speed | Slower | Faster |

| Surface Finish | Excellent | Very smooth |

| Batch Size | Small batches | Large batches |

| Applications | Aerospace, medical, military | Automotive, electronics, appliances |

💡 Key takeaway: Investment casting is best in case your project requires complex shapes, fine, and small batches. Die casting is superior to alternative forms in the event that you require high-volume production at low cost and quicker turnover.

Applications in Industry

Investment Casting Applications

Investment casting, also known as lost-wax casting, offers several key advantages, making it ideal for manufacturing parts that require intricate geometries and high precision. It is extensively used in industries where complex shapes and tight tolerances are critical. Below are the applications for investment casting in various sectors:

| Industry | Applications | Examples of Parts |

| Aerospace | Parts requiring high precision, lightweight, and high-strength materials | Turbine blades, engine components, exhaust nozzles, structural parts |

| Medical Devices | Medical implants and devices that demand high biocompatibility and precision | Hip replacements, dental implants, surgical tools |

| Military | Durable and precise parts for defense systems and weaponry | Gun parts, armor plates, military vehicle components |

| Automotive | High-performance, lightweight components requiring precision | Turbochargers, fuel injectors, valve seats, exhaust manifolds |

| Energy | Parts for power generation, including turbines and valves | Steam turbine blades, power plant components, valve bodies |

| Industrial Equipment | High-quality components for machinery and tools | Pumps, valve bodies, gear components, compressor parts |

Practically, investment casting technology has evolved into various subtypes, among which silica sol investment casting has become increasingly popular. Silica sol casting, in contrast to traditional water glass casting, offers greater accuracy, tighter tolerances, improved surface finish (Ra ≤ 1.6 μm), and low deformation, which is why it is widely applied in stainless steel and alloy components requiring high corrosion resistance and dimensional stability. As an example, at Bessercast, we specialize in the manufacture of high-quality stainless steel components using silica sol investment casting. Our decades of experience and advanced production lines help clients in the automotive, pump valve, and marine industries achieve stable performance, reduced machining costs, and superior product consistency.

Die Casting Applications

Die casting is a fast production system with high volume and is applied in making precise reliable parts. It is especially handy to those industries that need a lot of metal components that have finer details. The applications in the various sectors are as below:

| Industry | Applications | Examples of Parts |

| Automotive | Mass production of parts for vehicles, especially for engine components and body parts | Engine blocks, gearboxes, transmission housings, wheel rims |

| Consumer Electronics | Quick production of lightweight, durable enclosures and internal parts | Smartphone cases, laptop chassis, TV frames, camera bodies |

| Industrial Equipment | High-volume production of parts for machinery and heavy equipment | Pump housings, compressor bodies, pressure die-cast valves |

| Home Appliances | Production of high-quality, durable parts for various household products | Electric fan blades, appliance casings, motor parts |

| Telecommunications | Parts for communication devices and equipment | Antenna parts, brackets, enclosures for telecom equipment |

| Toys and Recreation | Lightweight, durable components for toys and recreational products | Toy components, bicycle frames, recreational vehicle parts |

Cost & Efficiency Considerations

In comparing the two casting modes of investment casting and die casting in terms of cost and efficiency, one should consider a number of factors. Investment casting is less expensive in terms of mold, yet the slower rate of production and higher costs-per-unit could render it expensive in large production quantities. But in the case of batch production of high-precision parts with greater design flexibility in small quantities.

Die casting, on the other hand, has fast production rates, hence suitable when production is in large quantities. Although the initial price of the mold is more expensive, it may prove to be cheaper in projects that demand large quantities of parts. Die casting is a more effective process in terms of time and cost when it comes to mass production due to the ability to make parts fast and of consistent quality.

How to Choose Between Investment Casting and Die Casting

To make a decision between investment casting and die casting, several factors need to be considered:

- Investment casting is preferable when your material is steel, titanium, or any other high-precision metal.

- If you have aluminum or zinc material and need to produce in high volumes, then die casting is your solution.

- Investment casting is preferable for complex shapes and small production in batches.

- Die casting will be more suitable if you have higher production volume per unit costs, coupled with high-volume parts.

Conclusion

To sum up, investment and die casting can present their own advantages or disadvantages based on the needs of your project. Investment casting is ideal in high-precision and complex components that are manufactured in smaller quantities, whereas die casting is ideal for manufacturing high quantities of parts that are highly repeatable and efficient.