Expert Quality Control Team

At BESSER, our 17 experienced quality experts lead the charge in upholding strict production standards. Their vast expertise ensures every casting adheres to top global benchmarks, delivering reliable solutions to clients across diverse industries worldwide.

ISO9001

IATF16949

ISO14001

ISO45001

ROHS

REACH

Ultrasonic Inspection Report

Dimensional Inspection Report

Chemical Composition Report

Mechanical Property Test Report

X-ray Digital Imaging Test Report

CMM Dimension Report

Uncompromising Quality You Can Rely On

BESSER sustains high quality with international certifications, detailed testing reports, and rigorous process oversight, delivering castings that comply with global industry standards.

— 100% traceability —

Rigorous Testing for Premium Cast Parts

Our professional team conducts thorough testing at every stage of production to guarantee the quality and performance of each part.

Raw Material Testing

BESSER maintains strict raw material inspection protocols to ensure quality from the source:

- Supplier certification review for all incoming materials.

- Systematic internal sampling and testing procedures.

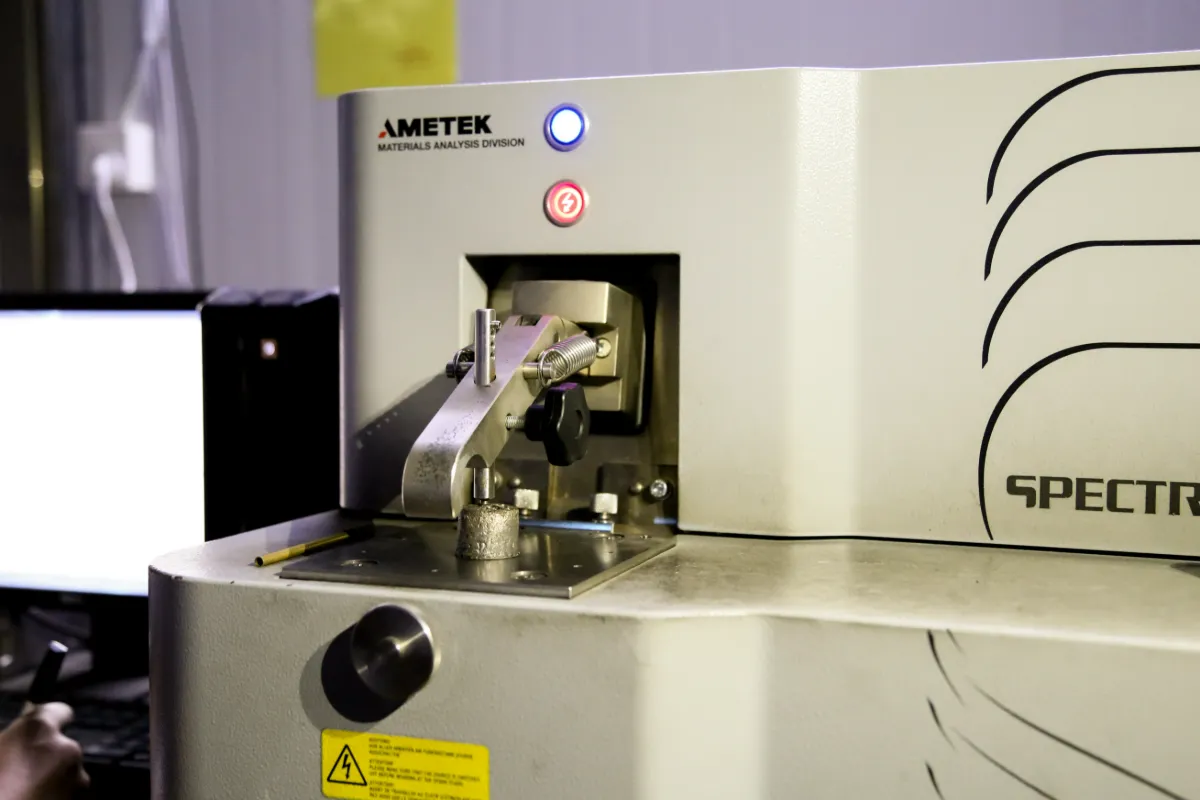

Chemical Composition Testing

We employ German Spectro spectrographs for precise chemical analysis before casting. Our pre-mixing approach ensures exceptional metal chemistry stability, eliminating variables in furnace operation. Each shipment includes detailed composition reports verifying compliance with customer material specifications.

Mechanical Property Testing

Our comprehensive testing equipment ensures products meet or exceed industry standards:

- Professional tensile testing machines for strength and elongation measurements.

- Brinell and Rockwell hardness testers for precise hardness verification.

Dimensional Accuracy Testing

Our precision measurement arsenal includes Swedish Hexagon coordinate measuring machines, profile projectors, calipers, and micrometers. Custom inspection gauges are designed in-house and verified by CMM for accuracy, enabling 100% product verification and specialized control of critical dimensions.

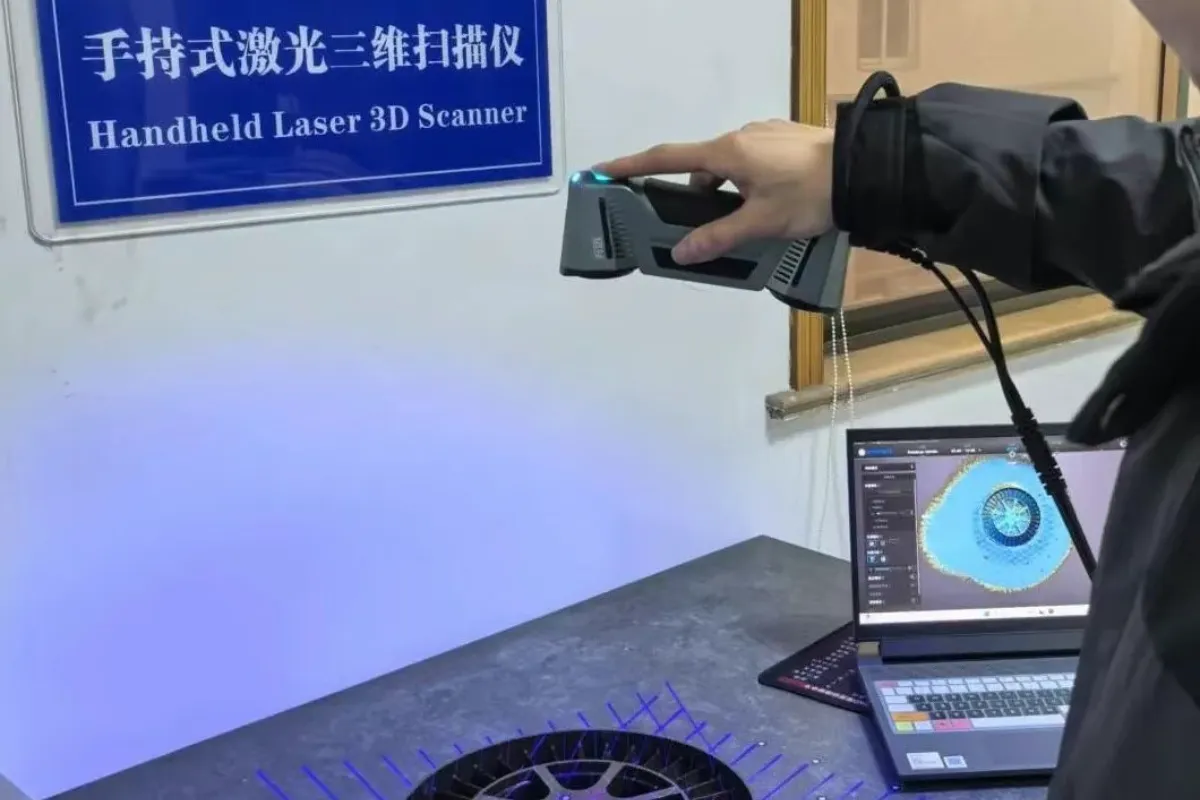

3D Scanning Inspection

As a critical addition to dimensional accuracy control, BESSER incorporates non-contact 3D scanning to enable full-dimensional quality verification of complex geometries and freeform surfaces:

- High-speed scanning captures complete 3D data of the entire part

- Deviation analysis through color map comparison with CAD models for rapid discrepancy detection

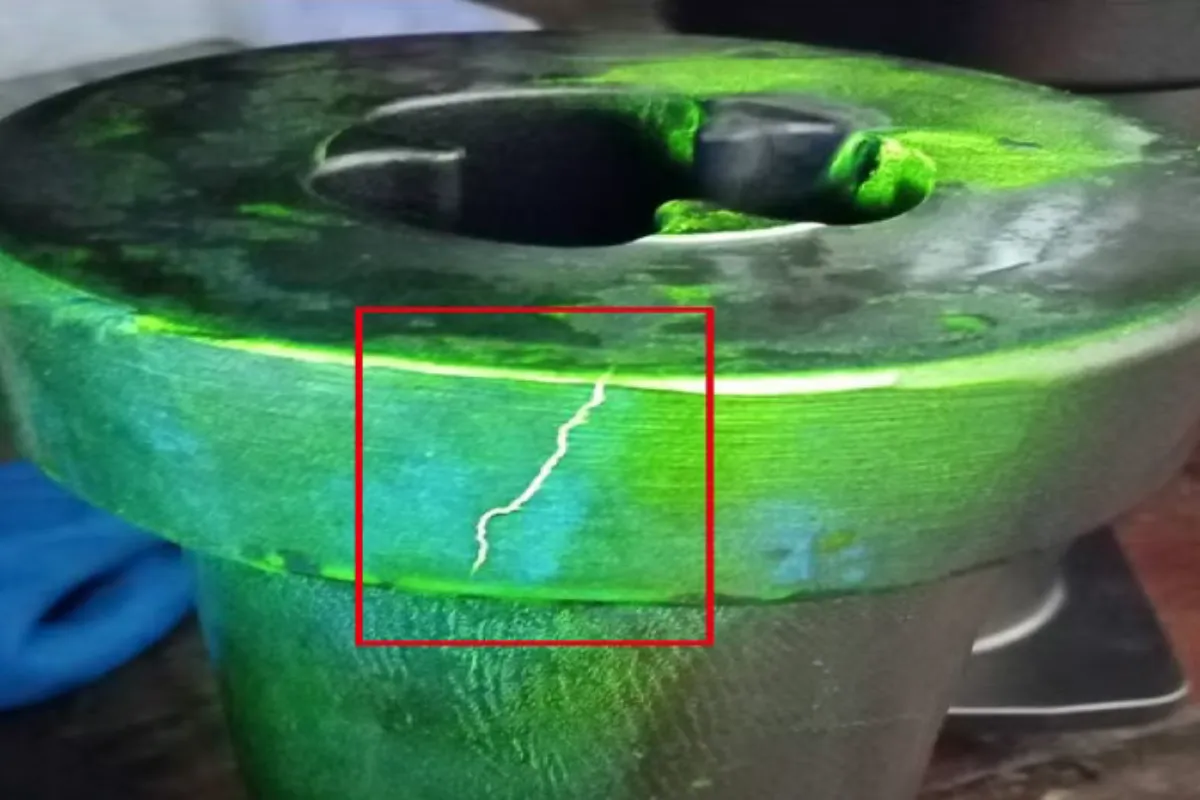

Surface Quality Testing

Achieving fine surface finishes down to Ra3.2, our surface quality control stands as a core BESSER competitive advantage, verified through:

- Magnetic particle testing for surface and near-surface defect detection

- Fluorescent penetrant testing for microscopic crack identification

- Microscopic examination and borescope inspection for thorough surface evaluation

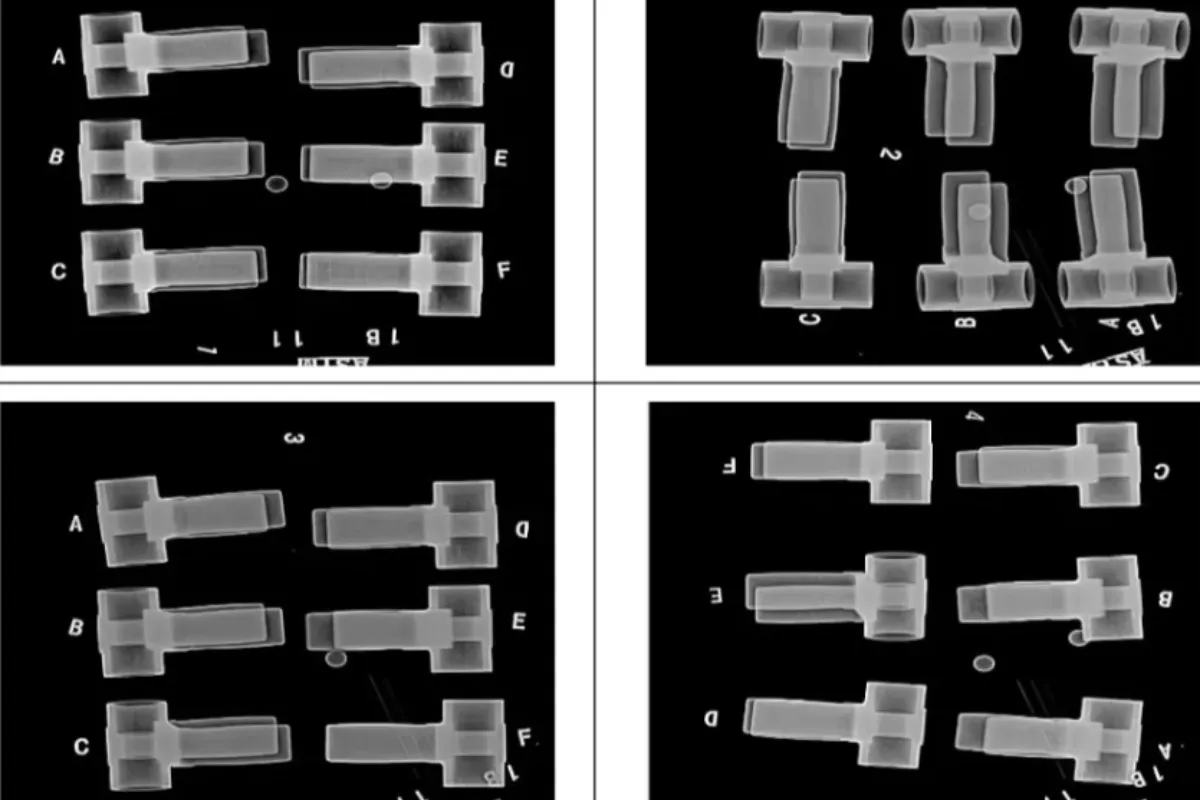

Internal Quality Testing

We ensure internal structural integrity using advanced non-destructive testing:

- X-ray inspection with dual and triple pole capability

- Ultrasonic testing for internal discontinuity detection

- Specialized pressure tightness testing for sealing performance

Corrosion Resistance Testing

Our 24/7/365 salt spray testing chamber simulates harsh environmental conditions, thoroughly evaluating product corrosion resistance to ensure long-term reliability in real-world applications.

Advanced Testing Equipment Solutions

Laser 3D Scanner

Ultrasonic Testing Equipment

X-ray Testing Equipment

German Spectro Spectrograph

Swedish Hexagon CMM

Tensile Testing Machine

Brinell Hardness Tester

Rockwell Hardness Tester

German Spectro Spectrograph

Swedish Hexagon CMM

Tensile Testing Machine

Brinell Hardness Tester

Rockwell Hardness Tester

Profile Projector

4 Million Pixel High-Definition Microscope

Surface Roughness Tester

Salt Spray Testing Chamber

German Spectro Spectrograph

Swedish Hexagon CMM

Tensile Testing Machine

Brinell Hardness Tester

Rockwell Hardness Tester

Profile Projector

4 Million Pixel High-Definition Microscope

Surface Roughness Tester

Salt Spray Testing Chamber

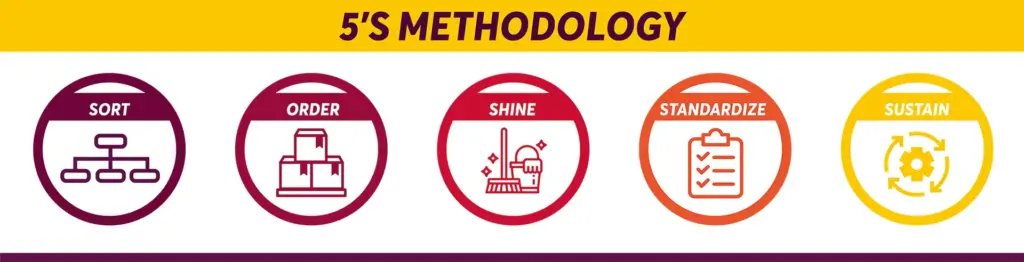

5S Workshop Management

BESSER implements 5S methodology across quality operations for maximum testing accuracy. Our quality team conducts regular audits, maintains visual management boards, and organizes workspaces for optimal efficiency. Daily cleaning protocols prevent contamination effects on precision measurements, supporting our commitment to superior quality results.

Continuous Improvement & Innovation

Daily Quality Circle Meetings

Production and quality teams conduct daily reviews of key performance indicators, addressing emerging issues immediately. These exchanges prevent quality concerns from impacting customer deliveries.

Customer-Driven Improvements

BESSER transforms quality feedback into actionable enhancements. Our systematic analysis of customer requirements drives process modifications, establishing measurable quality objectives for continuous advancement of casting capabilities.

Evolving Quality Procedures

Detailed SOPs govern quality control throughout production. Regular updates incorporate improvements, advancements, and lessons learned, building knowledge that elevates casting standards.