Introduction

It may be difficult to locate a trusted investment casting manufacturer, particularly when your project requires accuracy, finish surface, and material quality. Investment casting (also called the lost wax casting process) is the gold standard in the production of high-quality and complex metal components in 2025. This guide will assist you to learn the process of investment casting, consider the main aspects such as quality control and material expertise, and discuss the top 10 investment casting manufacturers in the world that are the leaders in the industry. You may require titanium components of aerospace grade, stainless steel valves, or complex aluminum parts. This list will refer you to reliable partners who will provide precision, consistency, and value at all times.

What is Investment Casting?

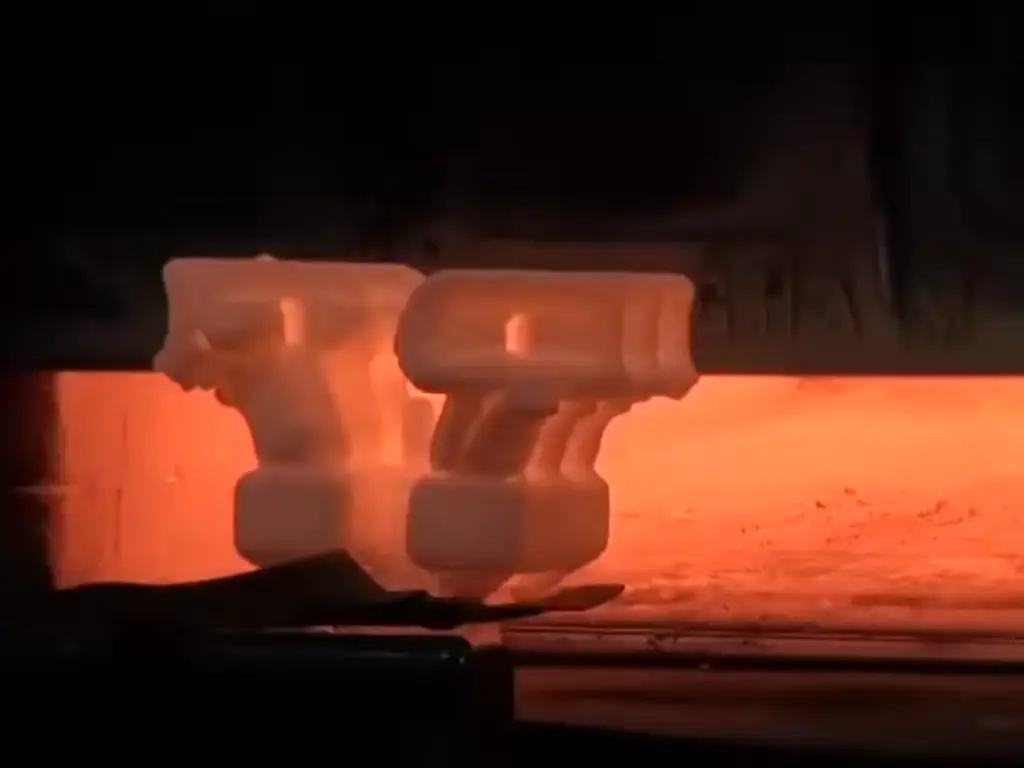

One of the most sophisticated and ancient processes of casting metals is investment casting, the origins of which date back thousands of years. It starts with the production of a wax pattern, which is a copy of the end product. The pattern is dipped into a ceramic slurry again and again to create a strong ceramic shell. When the shell has hardened, the wax is melted away–so the name is lost wax casting–and a hole is left in which to pour in molten metal.

The metal, be it stainless steel, carbon steel, or aluminum, is poured into the shell, cooled, and discharged to produce a perfect metal component. The result? High precision, high surface finish, and low machining requirements. Precision investment casting is best suited to industries where tolerances, performance, and reliability are the most important factors due to its ability to support a large variety of different alloys and complex geometries.

Common Applications of Investment Casting

The flexibility of the investment casting process and the capability to produce complex metal parts have enabled it to be used in a variety of industries.

In aerospace, lightweight turbine blades and structural parts that are of extreme performance are made possible through investment casting. It is used in the medical field in surgical instruments, implants, and prosthetics where precision and biocompatibility are not negotiable. It is used by automotive manufacturers in turbocharger wheels, rocker arms, and exhaust manifolds that resist heat and stress. In the meantime, stainless steel castings and carbon steel castings are used in valves, pumps, and housings in high-pressure, corrosive conditions in oil and gas and renewable energy industries.

This flexibility is due to the capability of the process to work with almost any metal alloy, tolerances, and provide durable quality parts. No wonder investment casting manufacturers still lead the way in modern manufacturing.

Key Factors for Choosing an Investment Casting Manufacturer

Choosing the appropriate investment casting manufacturer is not only a matter of price comparison, but also a matter of finding a long-term casting partner that will really know your product and priorities. In assessing the potential suppliers, pay attention to the following key aspects:

| Factor | Key Considerations |

| 1. Technical Capability | • Check if they manage core processes in-house such as wax injection, ceramic mold creation, metal casting, and CNC machining. • Review their experience with different alloys—from stainless steel and carbon steel to tool steel and superalloys. • Confirm their ability to handle heat treatment, surface finish, and tight tolerances for complex parts. |

| 2. Quality Control | • Leading investment casting manufacturers maintain strict quality control from raw material inspection to non-destructive testing (NDT) and final inspection. • Look for certifications like ISO 9001 or AS9100, and ask about internal audit practices. • Ensure they use modern tools such as spectrometers and coordinate measuring machines (CMM). |

| 3. Lead Times and Production Capacity | • Evaluate how quickly they can deliver—short lead times are essential to maintain a global supply chain. • Ask if they can scale production to meet future demand. • Confirm whether they provide rapid prototyping or small-batch production for new projects. |

| 4. Customer Service and Communication | • Dependable investment casting partners offer clear communication and full engineering support from design to delivery. • Seek companies that provide Design for Manufacturability (DFM) advice to help reduce production costs. • Consistent, transparent communication is the best sign of reliability. |

| 5. Continuous Improvement | • The best manufacturers embrace continuous improvement through automation, process optimization, and employee training. • This approach ensures quality parts, higher efficiency, and fewer production errors over time. |

Top 10 Investment Casting Manufacturers

Precision Castparts Corp. (PCC)

- Recommendation: ☆☆☆☆☆

- Website:www.precast.com

- Key Products: Superalloy turbine blades, jet engine components, energy systems

- Key Services: Precision investment casting, heat treatment, CNC machining, inspection

- Main Markets: Aerospace, oil & gas, power generation

Precision Castparts Corp. (PCC) is a leading investment casting manufacturer in the world, producing complex, mission-critical parts to the most challenging industries in the world. Their production process incorporates all the steps of wax pattern production to the final machining of the castings, which gives them the opportunity to control the quality and consistency of the final product.

PCC is known to have expertise in superalloy and titanium and its components are used in aircraft engines, turbines, and energy systems across the globe. They uphold high quality standards by having highly developed internal audits, whereby all metal parts are within specific tolerances. Their innovation is also a major strength as PCC invests in R&D and rapid prototyping. Their brand name has been associated with quality, workmanship and engineering superiority in the international investment casting sector.

| What We Love | Things to Consider |

| Unmatched quality and precision | High minimum order volumes |

| Expertise in superalloys & titanium | Long lead times for complex builds |

| Global footprint & customer support | Focused mainly on aerospace |

Besser Casting

- Recommendation: ☆☆☆☆

- Website:www.bessercast.com

- Key Products: Pump housings, valve parts, medical tools

- Key Services: Silica Sol investment casting, machining, finishing

- Main Markets: railway, pumps & valves, agricultural machinery

Besser Casting focuses on Silica Sol investment casting, which is known to provide high surface finishes and close dimensional tolerances. The company specializes in manufacturing metal parts of high quality that are used in the industries like railway systems, agricultural machinery and heavy industrial equipment where strength, durability and precision are critical. Their engineering team has a combination of high technical skills and the current automation to make sure that each casting is of the highest performance standards.

The metal casting process used by the company ensures that the parts are of consistent quality and require minimum post-machining. Besser Casting provides all casting projects with early design to final inspection by focusing on flexibility, precision, and customer service. Their stringent quality control system and adherence to short lead times enables them to provide quality solutions that are reliable and cost effective to their clients who require strong and durable components in the industrial and transportation industry.

| What We Love | Things to Consider |

| Excellent surface quality | Medium-scale operation |

| Great communication | Limited export reach |

| Strong medical and industrial focus | Narrow material range |

Signicast

- Recommendation: ☆☆☆☆☆

- Website:www.signicast.com

- Key Products: Stainless steel and carbon steel castings

- Key Services: Automated investment casting, machining, surface treatment

- Main Markets: Industrial equipment, medical, agriculture

Signicast is a highly technologically advanced manufacturer of investment casting in the United States, which is characterized by a combination of automation, precision, and speed. Their casting is digitally controlled, and each pour has the same metallurgical quality. This automation saves lead times by a significant margin and ensures world-class consistency.

Their plants are 24/7, and even complicated parts have short lead times. Signicast provides end-to-end service, including wax injection, heat treatment, and excellent customer communication and fast prototyping. Their emphasis on constant improvement and low production costs makes them an investment casting provider of choice to clients who require scalability without sacrificing quality.

| What We Love | Things to Consider |

| Exceptional automation and consistency | Less flexible for small custom runs |

| Fastest turnaround in the industry | Mainly U.S.-based |

| Transparent project communication | Limited exotic alloy support |

Hitchiner Manufacturing Co., Inc.

- Recommendation: ☆☆☆☆

- Website:www.hitchiner.com

- Key Products: Engine components, transmission systems, aerospace structures

- Key Services: Counter-gravity casting, finishing, quality inspection

- Main Markets: Automotive, aerospace, defense

Hitchiner Manufacturing is a leader in counter-gravity metal casting, a proprietary process that creates lighter and stronger parts. They have more than 50 years of experience, and they are among the most reputable manufacturers of investment casting in North America.

Their metal casting technique minimizes wastage of materials, increases structural integrity, and achieves tight tolerances in large volume production. They have the best quality control systems and have sophisticated methods of inspection and automated data capture that make them reliable. The years of experience in automotive applications make Hitchiner suitable for the projects where precision casting and short lead times are required.

| What We Love | Things to Consider |

| Innovative counter-gravity process | More automotive-focused |

| Low material waste | Requires larger volumes |

| Proven reliability | Limited to certain alloys |

Wisconsin Precision Casting Corporation

- Recommendation: ☆☆☆☆

- Website:www.wisconsinprecision.com

- Key Products: Aerospace, defense, and medical castings

- Key Services: Wax patterning, ceramic mold making, CNC machining

- Main Markets: Aerospace, defense, medical

Wisconsin Precision Casting Corporation is a reputable U.S. based investment casting manufacturer that deals with precision investment casting of stainless steel, carbon steel and tool steel. They have a reputation of quality control and strict tolerances that have seen them become a trusted supplier to the aerospace and defense industries.

The manufacturing process of the company incorporates design consultation, rapid prototyping and full scale production. They are certified to ISO 9001 and AS9100 and their internal audits guarantee uniform excellence. Wisconsin Precision offers the ideal mix of technical depth and customer service to customers who appreciate both.

| What We Love | Things to Consider |

| Aerospace-grade certifications | Slightly longer setup times |

| Excellent alloy expertise | Mid-range production scale |

| Comprehensive quality checks | U.S.-centric operations |

Doncasters Group

- Recommendation: ☆☆☆☆☆

- Website:www.doncasters.com

- Key Products: Superalloy turbine blades, power components

- Key Services: Investment casting, heat treatment, finishing

- Main Markets: Aerospace, energy, automotive

Doncasters Group is a well-known brand among the top investment casting producers and its metallurgical history dates back to over two centuries. Their production process focuses on high precision, surface finish and extreme condition durability.

Doncasters serves clients worldwide and deals with various alloys, including nickel superalloys and carbon steel. They are dedicated to constant improvement and quality standards, which guarantee high-quality metal castings that are above specifications. Their extensive international supply chain has made them an investment casting partner of choice for most OEMs.

| What We Love | Things to Consider |

| Worldwide operations | Higher costs |

| Deep metallurgical expertise | Large order preference |

| Excellent engineering support | Complex corporate structure |

CIREX

- Recommendation: ☆☆☆☆

- Website:www.cirexfoundry.com

- Key Products: Stainless steel precision components

- Key Services: Lost wax casting, machining, design support

- Main Markets: Automotive, defense, industrial

CIREX is a highly developed investment casting foundry in Europe with a reputation of automation and engineering quality. Their investment casting process combines robotics and quality inspection throughout the process, which guarantees high repeatability and lead times.

They are also specialists in carbon steel, tool steel and stainless steel castings and assist customers in rapid prototyping and technical advice. Through innovation and cost-efficiency, CIREX can be a preferred manufacturer of investment castings of high volume and specialized production.

| What We Love | Things to Consider |

| Strong European presence | Moderate lead times |

| Sustainable manufacturing | Limited North American access |

| High automation level | Mid-tier customization options |

Feinguss Blank GmbH

- Recommendation: ☆☆☆☆☆

- Website:www.feinguss-blank.de/en/

- Key Products: Industrial machinery, medical devices, energy components

- Key Services: Investment casting, finishing, assembly

- Main Markets: Industrial, renewable energy, medical

Feinguss Blank GmbH is the epitome of German accuracy. Being a major manufacturer of investment castings, it offers turnkey metal casting services-including wax injection, ceramic shell preparation and final casting. They are ahead of their competitors because of their internal audits and emphasis on continuous improvement.

The manufacturing process of Feinguss Blank focuses on sustainability, efficiency, and close tolerances. They assist customers to optimize designs, enhance surface finish and reduce production costs. They are a pillar of the European investment casting industry due to their combination of craftsmanship and modern automation.

| What We Love | Things to Consider |

| Renowned German engineering | Premium pricing |

| Full-service production chain | Mainly European focus |

| Strong commitment to innovation | Longer project onboarding |

Vaupell

- Recommendation: ☆☆☆☆

- Website:www.vaupell.com

- Key Products: Aerospace interiors, defense parts

- Key Services: Metal casting, design support, CNC machining

- Main Markets: Aerospace, defense

Vaupell is a reliable investment casting supplier of aerospace and defense customers, providing accuracy in investment casting and CNC machining of complex metal components. They have their products in critical aircraft structures and interior systems where reliability is crucial.

Vaupell has years of experience and high quality control systems that guarantee tight tolerances and uniform surface finish. Their customer-focused customer service and cooperative engineering culture qualify them as a good option in high-performance industries.

| What We Love | Things to Consider |

| Exceptional aerospace expertise | Limited to niche markets |

| Great technical collaboration | Smaller production capacity |

| Strong quality system | Higher project costs |

TITAL GmbH

- Recommendation: ☆☆☆☆☆

- Website:www.howmet.com/tital

- Key Products: Titanium and aluminum castings

- Key Services: Casting, machining, heat treatment

- Main Markets: Aerospace, industrial, defense

TITAL GmbH is a subsidiary of Howmet Aerospace and is among the most modern manufacturers of investment casting in titanium and aluminum alloys. They are experts in the manufacture of complex lightweight metal parts that are strong, corrosion-resistant, and free in design.

The manufacturing process of TITAL involves the use of state-of-the-art ceramic molds, heat treatment, and CNC machining to produce high-quality surface finishes and tight tolerances. Their dedication to constant improvement, technical perfection, and quality customer service makes them one of the most popular investment casting manufacturers in the world.

| What We Love | Things to Consider |

| Titanium & aluminum expertise | Large order orientation |

| Excellent process control | Longer setup times |

| Outstanding aerospace quality | High entry cost |

Besser: Your trusted manufacturer

BesserCast is a reputable manufacturer of investment casting, which has certified facilities (IATF 16949, ISO 9001, ISO 14001) and an annual capacity of 3,000 tons. We offer one-stop solutions of CNC machining to surface treatment with the help of advanced casting-simulation software and quality control. We have 4,500+ custom parts, 200 alloy grades, and export over 12 countries, and we are integrating innovation, flexibility, and reliability to satisfy the global industrial needs.

Are you ready to begin your next project? Call BesserCast today and request precision castings that provide strength, performance and value.

Conclusion

The success of your whole casting project can be determined by the choice of the best investment casting manufacturers. With a review of the technical capabilities, lead times and quality control of each company, you will have the ideal investment casting partner who will not only provide parts- but performance.

Ready to take your next step? Call our engineers now to have a free project consultation. We will then turn your ideas into quality castings with tight tolerances, high surface finish, and unparalleled precision, and assist your business in producing the highest quality at reduced production costs.