Introduction

In any engineered component, the choice of manufacturing process is a crucial decision. Investment casting and sand casting are two industrial giants among the metal casting techniques. Although both convert molten metal into a working part, their similarities end there. Making the wrong decision is a road to cost increases and failure. It is a practical deep dive for an engineer, and it gives you a clear outline on how to make the right decision on the right application.

Understanding the Fundamental Processes

In order to compare the two casting techniques, one must be aware of the different procedural steps of each technique. Their respective processes differ, which is why they have different technical capabilities and limitations.

Sand casting

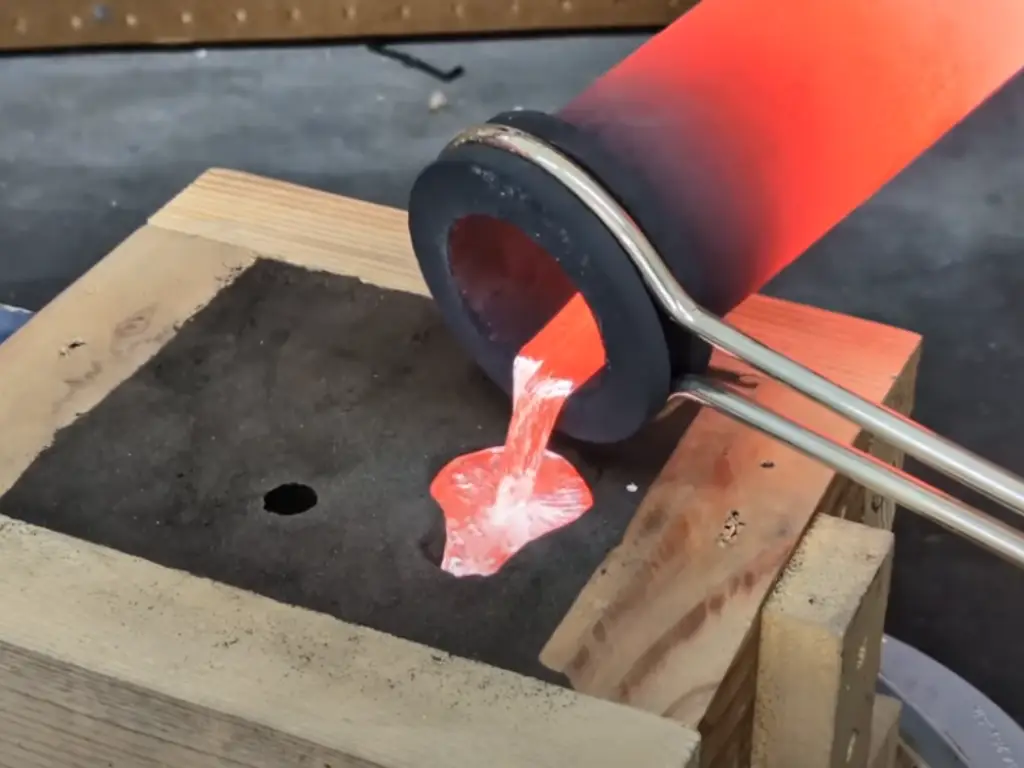

Sand casting is a manufacturing method that is considered to be a fundamental method of manufacturing a variety of parts due to its efficiency. It starts with the formation of a mold with the help of an aggregate based on sand, usually green sand. A pattern of the part, usually of wood or a polymer, is pressed into the sand to create a negative cavity. In case the design has internal cavities, then accurately cut sand cores are inserted into this mold. The two parts of the sand mold are then firmly joined together and molten metal is poured into the mold. After cooling and solidification, the disposable sand mold is chipped off to recover the raw metal casting.

| Step | Action | Description |

| 1 | Pattern Making | A reusable pattern of the final part is created, typically from wood, polymer, or metal. It includes allowances for shrinkage. |

| 2 | Mold & Core Making | The pattern is pressed into sand to create the mold cavity. Separate sand cores are made to form internal features. |

| 3 | Mold Assembly | The two halves of the sand mold (cope and drag) are assembled, and the cores are placed inside. |

| 4 | Pouring | Molten metal is poured into the gating system of the assembled mold and fills the cavity. |

| 5 | Solidification | The metal is allowed to cool and solidify, taking the shape of the mold cavity. |

| 6 | Shakeout & Cleaning | The sand mold is broken away from the casting. The gating system and risers are removed, and the part is cleaned. |

Investment casting

Investment casting or the lost wax process or the wax casting is a multi-step process that is designed to create parts that are highly precise and have intricate features. It begins with the creation of a wax pattern which is a perfect copy of the completed part. Several patterns are commonly mounted on a central sprue of wax, creating a tree. This is then immersed in a series of immersions in a liquid ceramic slurry, and then a coating applied of a fine refractory material. This process is continued until a hard ceramic shell of sufficient thickness is produced. The whole is then heated in a furnace or autoclave to melt the wax, leaving behind a hollow, smooth ceramic mold. This is followed by the pouring of molten metal into this pre-heated mold. Once the metal has solidified the ceramic shell is then removed mechanically, leaving behind a very detailed, almost net-shaped metal component.

| Step | Action | Description |

| 1 | Pattern Injection | Molten wax is injected into a metal die to create a precise, sacrificial pattern of the final part. |

| 2 | Pattern Assembly | Multiple wax patterns are attached to a central wax sprue and gating system, forming a “tree.” |

| 3 | Shell Building | The tree is repeatedly dipped into a ceramic slurry and coated with refractory sand to build a robust ceramic shell. |

| 4 | Dewaxing (Burnout) | The assembly is heated in an autoclave or furnace, causing the wax to melt and drain out, leaving a hollow ceramic mold. |

| 5 | Pouring | The pre-heated ceramic mold is filled with molten metal, often under vacuum or controlled atmosphere. |

| 6 | Knockout & Finishing | Once cool, the ceramic shell is broken and vibrated away. The parts are cut from the tree and finished as required. |

Head-to-Head: A Technical Specification Comparison

Knowing the processes is one thing and knowing how they are translated into tangible engineering specifications is another. It is the data that matters to the critical engineer. We place the two methods in a head-on, side-by-side crucible.

| Specification | Investment Casting | Sand Casting |

| Surface Finish | Excellent (63-125 µin Ra) | Rough (250-1000 µin Ra) |

| Dimensional Accuracy | High (±0.005 in/in) | Low (±0.030 in for first inch) |

| Typical Part Size | Ounces to ~150 lbs | Pounds to many tons |

| Wall Thickness | Very thin (~0.040 in) | Thick (~0.250 in minimum) |

| Tooling Cost | High | Low |

| Unit Production Cost | Lower in high volume | Higher due to labor/machining |

| Lead Time | Longer | Shorter |

| Design Complexity | Virtually unlimited | Limited, requires draft angles |

Dimensional Accuracy and Tolerances

The first gate that an engineering design will have to pass is dimensional accuracy. Precision is the most important in parts that need to fit perfectly in a complicated assembly. It is here that investment casting claims its supremacy. Since it is made with a solid, single-piece, ceramic mold produced using a very precise die, it can be produced with very tight tolerances. This dimensional accuracy is very high, and the cast part is very similar to the original CAD model.

By definition, sand casting has a reduced high-dimensional tolerance. The variability is increased by the shifting nature of sand, the minor changes in the packing of molds, and the need for a two-part mold. It does not make it a worse process, but it does render it unsuitable in processes where fractions of a millimeter can be the difference between success and failure.

Surface Finish and Post-Processing Needs

Walk into a workshop and put a raw investment casting beside a raw sand casting. The difference is palpable. The casting of the investment will be smooth, and it is a testimony to the fine ceramic slurry it was created. This is a very good surface finish, which is a very important economic consideration, since it greatly minimizes the secondary machining operations, which are expensive and time-consuming.

The sand casting components, which will have been cast against relatively coarse grains of sand, will have a rougher surface finish. This is quite sufficient in most applications. A mirror finish is not necessary in a pump housing or an engine block. Nevertheless, when a smooth surface is required (e.g., to seal, to perform fluid dynamics, or to be aesthetically pleasing), it will demand a lot of post-process machining, which will contribute to the overall labor costs and complexity of the manufacturing process.

Geometric Complexity and Part Integrity

The contemporary engineering is an endeavor of optimization, to make parts stronger, lighter and more efficient. This usually results in complicated designs having complicated features. Investment casting is good in making complex parts and complex shapes. Since the wax pattern can be shaped into virtually any shape and the ceramic shell is smooth, such details as thin walls, intricate geometries, and internal passages can be cast into the part. This enables the production of single, consolidated metal components which would otherwise have to be welded or bolted together.

Sand casting is more limited. The draft angles are required to draw the pattern out of the sand mold. Deep pockets and complex undercuts are hard or impossible to do. Although cores are capable of forming internal cavities, the total geometric freedom is much reduced, and it is not a good choice in the most complex parts.

The Deciding Factor: When Precision Is Non-Negotiable

In a large number of applications, the economical and strong quality of sand casting is the obvious winner. It is the undisputed champion when you have to make large parts or large components, where the raw strength is the more important consideration than the fine detail. However, in high-performance machinery, aerospace, medical equipment, and defense systems, there is a category of components where accuracy is not just an attribute; it is the fundamental principle of operation and safety.

In these applications, investment casting is the start and finish of the conversation. Where a turbine blade must support unbelievable forces and retain its perfect aerodynamic shape, where a surgical implant must fit the anatomy of a patient with the utmost accuracy, or where a valve body of a critical system must work, there is no place to allow the vagaries of a sand mold. The capability to create a final product that is close to net-shape, and needs very little finishing, maintains the integrity of the design and the purpose of the engineering team.

The Silica Sol Advantage for Demanding Applications

Nevertheless, not every investment casting technique is equal. Although the traditional investment casting is very precise, the silica sol casting process is a step further in this technique. We are the Bessercast and we are specialized in this high-tech process where we use silica sol as a binder in the ceramic slurry. This creates a more sophisticated and stable molding material, providing superior surface finishes and superior dimensional accuracy.

Silica sol forms molds with much finer detail and more fidelity to the original design than more traditional binders such as water glass. This is particularly important to the industries that require precision, durability, and performance like the railway, agricultural machinery, and pump and valve body manufacturing. The silica sol process is used to make sure that the parts we cast are of the highest quality whether it is high-strength components in rail transport, precision parts in agricultural equipment, or reliable valve bodies in fluid systems. In the case of engineers in these high-stress industries, this method provides some degree of assurance and quality that cannot be achieved by conventional investment casting methods.

A Practical Guide to Cost: Tooling vs. Total Value

The economic evaluation of a casting technique is seldom easy. The most frequent error is to compare the initial tooling costs only. In this case, sand casting is at a distinct advantage; the patterns are relatively cheap to make, and it is suitable to prototypes, small production batches, or when the design is expected to change frequently.

The investment casting tooling, a machined metal die to form the wax patterns, is a major initial investment. But to look at this figure is a false economy. The actual cost should be considered on the total volume of production. Since investment castings need much less machining, the unit price per part is much lower with volume. The less labor, less material waste, and less rejection rates imply that in the long run, investment casting can be the cheaper option in mass production. The work of the engineer is to look beyond the first invoice and determine the total value delivered in the completed part.

Application Deep Dive: Industry-Specific Use Cases

Theory becomes clear through application. Let’s examine where these processes are put to work:

Sand Casting: Imagine the industrial backbone. It is the preferred process of large parts in the automotive (engine blocks, cylinder heads, transmission cases), heavy equipment (gear housings, counterweights), and municipal infrastructure (manhole covers, large valve bodies). The fact that it can process a large amount of metal and manufacture extremely large components makes it an indispensable part of these industries.

Investment Casting: It is the world of high-technology and complex mechanics. Casting can be done with a lot of precision on a wide variety of materials such as exotic alloys and stainless steel. You will find its products in:

| Industry Sector | Example Components | Key Rationale / Requirements |

| Aerospace | Turbine blades, structural components, fuel system parts | Critical weight, geometric complexity, and material integrity are non-negotiable. |

| Medical | Orthopedic implants (hips, knees), surgical tools, dental prosthetics | High demand for biocompatibility, perfect anatomical form, and smooth surface finish. |

| Defense & Security | Firearm components, missile fins, drone parts | Absolute reliability, high-strength materials, and the need for near-net-shape parts. |

| Pumps & Valves | Complex valve bodies, pump housings, impellers | Requirement for leak-proof integrity, pressure resistance, and intricate internal cavities. |

| Energy Sector | Oil & gas exploration parts, power generation turbine components, sensor housings | Must perform reliably in extreme temperatures, high pressures, and corrosive environments. |

| Agriculture Machinery | Harvester blades, tiller tines, seeding equipment parts | High demand for durability, excellent wear resistance, and complex shapes to withstand harsh conditions. |

| Railway & Transit | Braking system components, door mechanisms, track switching parts | Production of high-strength, safety-critical components with excellent dimensional control. |

Your Project Checklist: Making the Right Call

To distill this complex comparison into a practical tool, ask yourself and your engineering team the following questions before committing to a process for your specific applications:

- What is my absolute required tolerance? When it is smaller than ±0.030″, then you should at once turn your attention to investment casting.

- Is surface finish critical for function or aesthetics? Investment casting will save you a lot of post-processing expenses in case the part requires a smooth and clean surface out of the box.

- How complex is my design? The more complicated the component, the better the argument in favor of investment casting.

- What is the anticipated production volume? Sand casting has a low tooling cost which is appealing to a few prototypes or a short run. The overall cost of investment casting is probably less in hundreds or thousands of parts.

- What is the size and weight of the part? Sand casting is among the limited options of components that weigh hundreds or thousands of pounds.

- Will the design likely change? If you anticipate frequent revisions, the lower-cost tooling of sand casting provides more flexibility.

Partnering for Success: Final Considerations & Next Steps

The decision to invest or cast in sand is very important, but not the only one. Other metal casting techniques have their own distinct benefits. Die casting is fast with non-ferrous metals such as aluminum, and centrifugal casting is a process that employs centrifugal force in a rotating mold to produce dense and pure cylindrical components. The manufacturing environment is huge.

After all, the success of your project is not only about the process you are going to use, but also about the partner you are going to implement it with. A skilled manufacturing partner is not merely a person who receives an order and fulfills it; he/she also give you design-for-manufacturability feedback, assist you in choosing the appropriate materials, and make sure that your quality specifications are met on each part.

The process of transforming a digital representation into a real, high-performing part is complicated. However, with the basic facts of these mighty manufacturing processes in mind, you will be able to make a confident decision that will be beneficial to your project, both in the initial prototype and in the last production run.