Ultrasonic Inspection

- Home

- Ultrasonic Inspection

What is Ultrasonic Inspection?

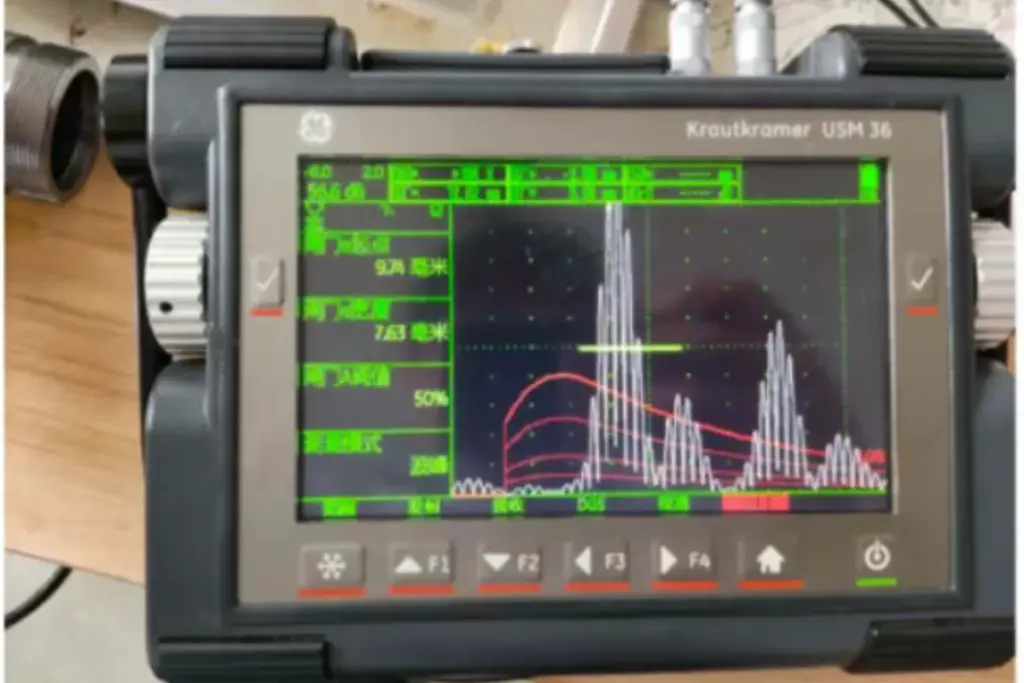

Ultrasonic testing (UT) is a non-destructive method that uses high-frequency sound waves (typically 500 KHz to 20 MHz) to detect internal defects or measure thickness in materials. When sound waves hit a flaw like a crack or void, part of the wave reflects back. By analyzing the time and pattern of these echoes—usually on an oscilloscope—technicians can locate and assess defects. UT is commonly used after forging and final heat treatment, and is effective for detecting cracks, inclusions, and porosity.

Advantage of Ultrasonic Inspection

High Detection Sensitivity

Ultrasonic testing offers exceptional sensitivity, capable of identifying minute internal flaws such as cracks, voids, and inclusions with high precision.

Deep Penetration Ability

It enables thorough inspection of thick-walled or large components, ensuring defect detection deep within the material.

Real-Time Results

The technique provides real-time data, allowing inspectors to assess defect location, size, and severity during the test process.

Minimal Surface Preparation

Unlike some other NDT methods, UT requires little surface treatment, reducing preparation time and operational downtime.

Versatile Application Range

It’s suitable for a wide range of materials and shapes, from metals to composites, and flat to curved surfaces.

Safe and Clean

UT uses sound waves, not radiation, making it safer for operators and cleaner for the environment.

Ultrasonic Inspection in Besser Foundry

At Besser Casting, we apply precise ultrasonic testing to detect internal defects early and accurately — ensuring every casting meets high-performance standards. With our technical expertise and commitment to quality, we help you reduce risk and improve reliability. Need castings with proven internal soundness? Reach out to Besser Casting today.

Partner with Besser for your next casting project and benefit from precision casting backed by cutting-edge inspection technology.