Introduction

The metal casting process is one of the pillars of modern manufacturing, which involves pouring molten metal into a mold to form a desired shape. The method is necessary in the creation of powerful and sophisticated metal components, including construction apparatus parts and accurate medical equipment. Nevertheless, the decision of a particular casting technique has far-reaching consequences on the ultimate cost of the part, the surface finish, and the dimensional accuracy. This guide will give you a detailed description of the various forms of metal casting, their main steps, and a guide to enable you to choose the appropriate method to use in your project.

What Are the 5 Steps of the Metal Casting Process?

No matter what particular technique is used, almost all metal casting processes have five basic steps. The initial step is usually the most important step, as it determines the ultimate geometry and quality of the part.

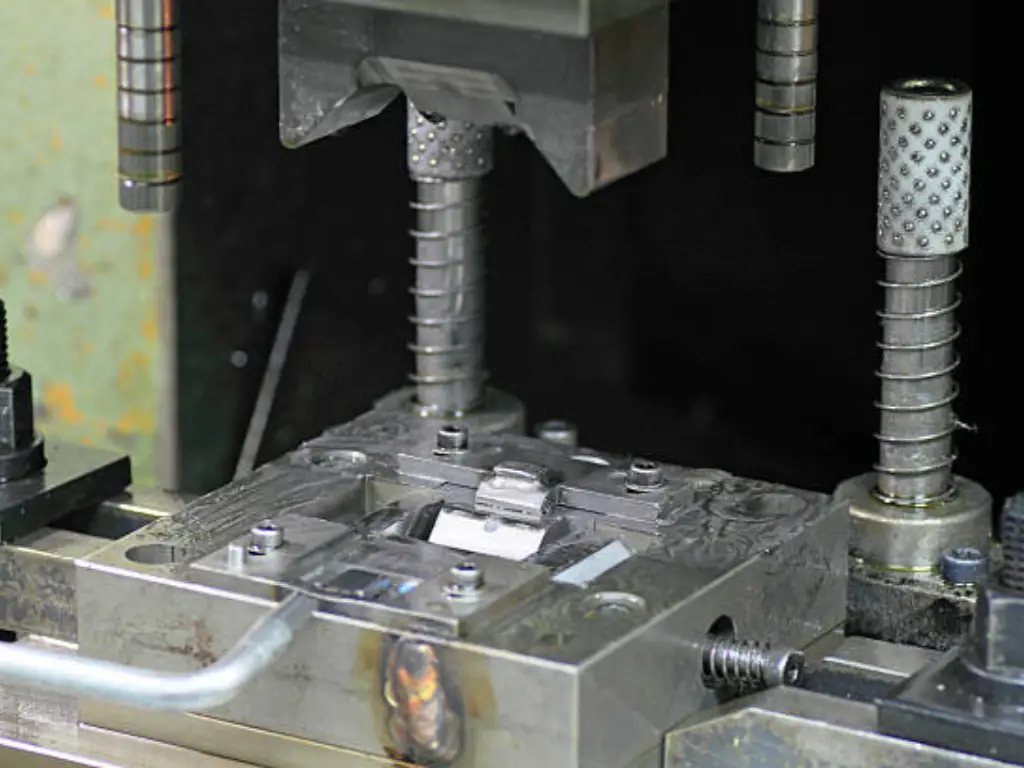

Moldmaking (or Patternmaking)

The first is the production of the mold, the tooling that holds the hollow shape of the final desired shape. This mold may be a disposable, non-permanent mold, such as a mold of sand (sand molding) or a permanent, reusable mold (or metal die), machined out of steel (die casting). In the case of expendable molds, the cavity is made by use of a pattern (a replica of the part). In case the last section needs internal hollows (such as an engine block), a separate core is created and inserted into the mold cavity.

Melting and Alloying

At the same time, the selected metal (such as cast iron or ferrous metals) or alloy (such as stainless steel) is heated in a furnace (such as an induction or electric arc furnace) until it reaches a certain pouring temperature, which converts it into a liquid metal or molten material. This is a very important step in metallurgy. To achieve the required mechanical and physical properties (such as high strength or resistance to corrosion) in the end product, the chemical composition and temperature must be carefully controlled.

Pouring (or Casting)

The molten metal is removed from the furnace, usually in a ladle, and poured into the cavity of the mold. Pouring is one of the major differences between metal casting techniques. It may be as simple as letting gravity fill the mold (in sand casting and permanent mold casting), or it may be forced under high pressure (in die casting process) or by centrifugal force (in centrifugal casting).

Solidification and Cooling

The liquid metal starts to cool and solidify in the shape of the cavity in the mold. This is not a passive process; the cooling rate should be controlled. As metals cool, they shrink. This should be expected in the shape of the mold (e.g., with risers that supply additional molten material) to avoid voids or porosity, which are typical casting defects.

Finishing and Inspection

The cast component is removed from the mold once it is completely solidified. In expendable mold processes, this is done by breaking the mold away (e.g., shaking out the sand). In reusable mold processes, the part is ejected. The part is not yet finished. It has to be operated to eliminate any surplus metal- the gates, runners, risers (the “plumbing” that fed the metal), or flash (metal that leaked between halves of the mold). This is usually sandblasted, ground, machined to tight tolerances or heat treated to improve the high strength and final properties of the part.

Expendable vs. Permanent Mold Casting: The 2 Main Categories

Thousands of casting variations fall into two primary categories, defined by the type of mold they use.

Expendable Molds

These are temporary molds that are destroyed to recover the cast component. Each casting requires the remaking of the mold. Sand casting, investment casting, plaster casting, and shell molding are all found in this category. Since the mold is cut off, this is the best way to make parts with complicated shapes and complex parts, including parts with internal cavities.

Permanent Molds (Reusable Molds)

These are molds, usually machined of steel, which are intended to be reused thousands of times. The most notable ones are permanent mold casting (gravity-based) and the die casting process. This is very cost-effective in mass production, and the rigid, non-destructive character of the mold restricts the geometric complexity of the parts that can be made.

Comparing the 3 Major Casting Techniques

While countless different types of metal can be cast, most industrial production relies on three primary techniques.

Sand Casting: For Large Parts and Low Tooling Cost

The most popular of all metal casting methods is sand casting. It is done by pouring a mixture of sand (usually green sand, a mixture of sand, clay and water) into a pattern. The pattern is eliminated, and a hole is left.

This is the foundation of heavy industry. Very large parts are made using it, including engine blocks, industrial pump housings, and construction equipment parts. It works very well with ferrous metals such as cast iron and steel. Its main strength is that it has a very low tooling cost and is very scalable in size. The trade-off is however high: sand casting gives a coarse surface finish and the lowest dimensional accuracy of the major types of casting, and may need much post-machining.

Die Casting: For High Speed and Mass Production

Die casting is a permanent mold casting. It is a process that entails the injection of molten metal into a hardened steel mold (a metal die) at very high pressure. This method of die casting is fast and efficient and can cast thousands of parts in one mold.

It is the process of choice of high volume metal products that need good surface finish and uniform dimensions. It is primarily applied to non-ferrous low-melting-point metals such as aluminum, zinc, and magnesium. The main limitations are that the die is very expensive to purchase and that it cannot be used with ferrous metals such as steel which have a high melting point that can destroy the die.

Investment Casting (Lost-Wax): For Complex Shapes and High Precision

Investment casting, also known as lost wax casting, is one of the most precise modern methods available. It is prized for its ability to produce parts with extreme detail and intricate shapes.

| Step | Process Description | Key Point |

| 1. Wax Pattern Injection | A precision injection mold is used to create a wax replica of the final part, known as a wax pattern. | This is an exact replica of the part. |

| 2. Pattern Assembly (Tree) | Multiple wax patterns are manually attached (welded) to a central wax runner system, forming a “tree” structure. | This increases efficiency for a single pour. |

| 3. Ceramic Shell Building | The entire wax tree is repeatedly dipped into a ceramic slurry, then coated with sand. Each layer is dried and hardened, building a robust ceramic shell. | This shell, built around the wax casting, becomes the actual mold. |

| 4. Dewaxing (Lost Wax) | The entire ceramic shell is placed in an autoclave (a high-pressure steam boiler) and heated. The wax patterns melt and drain out, leaving a hollow cavity. | This is where the name “lost wax” originates. |

| 5. Metal Pouring | The ceramic shell is fired at high temperature to remove any residual moisture and increase its strength. Molten metal is then poured into this pre-heated cavity. | Pre-heating the shell helps the liquid metal fill all complex shapes. |

| 6. Shell Removal | After the molten metal has fully solidified and cooled, the outer ceramic shell is broken away using vibration or water-jet blasting. | The expendable mold is destroyed to reveal the metal parts inside. |

| 7. Cut-off & Finishing | The metal parts are cut from the “tree” and undergo finishing operations like grinding and sandblasting to remove gate marks, resulting in the final part. | This produces a “near-net-shape” precision component. |

This method can create complex parts with undercuts and internal passages that are impossible to achieve with other casting methods.

Why Silica Sol Casting Excels in Precision

Although the term investment casting is equivalent to precision, there is an important difference in the technique: the kind of ceramic binder. These two are sodium silicate (water glass) and silica sol.

The better, more advanced binder is silica sol, and the key to the greatest precision.

The silica sol slurry offers superior chemical and thermal stability. This produces a stronger and less reactive mold with molten metal, particularly high temperature alloys such as stainless steel and other steel castings.

The advantages to the end product are direct and important:

- Excellent Surface Finish: Silica sol casting is used to create a very fine surface finish, which reduces the secondary polishing.

- Outstanding Dimensional Accuracy: It provides smaller tolerances and consistency of components unmatched by water glass or sand casting.

- Material Integrity: It is the perfect process of alloys that require high strength and strong mechanical properties because the non-reactive mold eliminates contamination and guarantees the purity of the physical properties.

- Reduced Casting Defects: The shell stability minimizes the chances of inclusions, cracks, and surface defects.

At Bessercast (https://www.bessercast.com/), we specialize exclusively in this advanced silica sol investment casting process. This specialization enables us to manufacture geometrically complicated components and complex components to the most challenging industries, including medical devices and aerospace components and high-performance durable goods. In applications where accuracy is of the essence, e.g. classic car parts that need perfect form and function, the silica sol technique offers an unmatched value, a near-net-shape cast component, which saves post-processing and machining expenses by a significant margin.

How to Select the Right Casting Process for Your Project

Choosing between these main types depends entirely on your project’s constraints: part complexity, volume, material, and cost targets.

Here is a simplified selection framework:

| Feature | Sand Casting | Die Casting | Investment Casting (Silica Sol) |

| Dimensional Accuracy | Low | High | Very High |

| Surface Finish | Poor to Fair | Good to Excellent | Excellent to Fine |

| Part Complexity | Low to Medium | Low to Medium | Very High (Intricate Shapes) |

| Tooling Cost | Very Low | Very High | Medium to High |

| Per-Part Cost | Low | Very Low (at high vol.) | Medium |

| Typical Materials | Cast Iron, Steel, Aluminum | Aluminum, Zinc, Magnesium | Stainless Steel, Steel Castings, Bronze |

Although these are the three most popular, there are other specialized techniques, including centrifugal casting (centrifugal force is used to form cylindrical parts such as pipes), shell molding (a resin-bonded sand shell is used to provide a better finish than green sand), vacuum casting (extremely high-purity melts), and continuous casting (to produce simple stock shapes such as bars and tubes).

Key Design Principles for Cast Parts (DFM)

In order to maximize any casting process, the parts should be designed to be manufacturable (DFM).

- Uniform Wall Thickness: This ensures that there is uniformity in the thickness of the wall, and this ensures that there is no differentiation in cooling and hence no shrinkage and casting defects.

- Draft Angles: In permanent mold casting and sand casting, vertical faces should be angled (drafted) slightly to enable the part to be removed out of the mold. One of the benefits of investment casting is that it needs no draft, allowing actual vertical walls and complicated shapes.

- Fillets: Rounding the internal corners (fillets) of a part reduces stress concentration and improves the flow of molten material, resulting in a part with high strength.

- Machining Allowance: If a surface requires extremely tight tolerances, extra material should be included in the casting design to be machined away during a finishing operation.

Conclusion: Choosing the Right Process and Partner

The metal casting process is an effective and flexible manufacturing tool, yet the quality of your end product is extremely reliant on the skills of your supplier. There is no such thing as the best casting technique, nor is there such a thing as the worst casting technique; it is simply a matter of your particular design.

In choosing a foundry, do not just choose the one with the lowest price quote. A supplier of large cast iron components to engine blocks might not be best suited to the manufacture of small, complex components of stainless steel, which might need other equipment and process controls.

Find a partner who has a proven track record of knowledge in your particular material and complexity needs. Inquire about their process control, their quality assurance and experience with parts of the same kind as yours. When your metal products require a high level of dimensional accuracy and a superior surface finish, which is best attained through such processes as silica sol investment casting, it is very advantageous to enlist the services of a specialist.

To consult the engineering team of Bessercast (https://www.bessercast.com) to design your next project, specializing in the production of complex parts into high-quality steel castings and metal parts to be used in demanding applications where precision and integrity are paramount.