Heat Treatment

- Home

- Heat Treatment

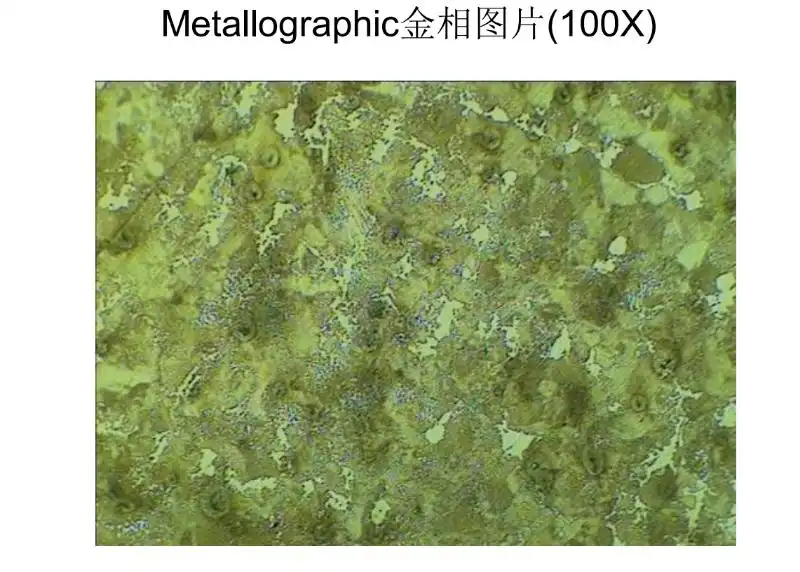

Heat Treatment: Maximizing Component Performance

Heat treatment is a controlled process used to enhance the strength, hardness, and durability of metals. BESSER specializes in precision heat treatment services, ensuring optimal mechanical properties for castings used in demanding industries like automotive, rail, and heavy machinery.

Types of Heat Treatment Processes

Tailored heat treatment services to meet demanding industrial standards and requirements.

Solution Treatment

Applied to materials such as nickel-based alloys and steel to adjust their structure, optimizing their mechanical properties for enhanced performance.

Quenching & Tempering

A two-step process that improves hardness and strength, primarily used for steel components like gears, shafts, and structural parts.

Carburizing

A process which raises surface hardness and is applied to parts such as gears, camshafts and other high-wear parts that must have greater wear resistance.

Nitriding

Used to enhance the wear resistance and corrosion resistance of materials, commonly applied in applications like engine components, tools, and industrial machinery.

Alloy penetration

Alloy penetration strengthens materials by diffusing elements into the surface, enhancing durability for high-performance parts like turbine blades.

Why Partner With BESSER

for Heat Treatment?

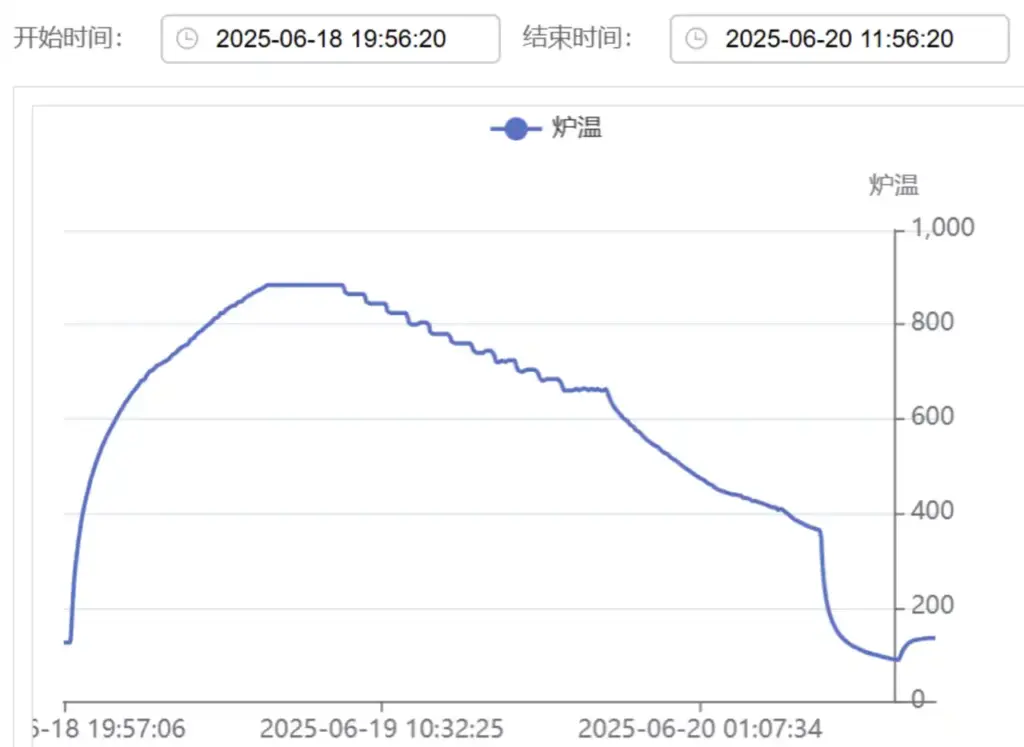

Precision Control

Our state-of-the-art heat treatment technologies allow us to achieve precise control over temperature and cooling rates, ensuring consistent results and superior mechanical properties.

Advanced Furnace Technology

Equipped with the latest furnace technology, we offer controlled atmospheres and optimal quenching techniques for achieving the best results, reducing defects and improving product reliability.

Customized Solutions

We tailor our heat treatment services to meet the specific material and performance requirements of each customer, ensuring that your products meet the highest quality standards.

Problems You’ll Never Face with BESSER

No delays from outsourcing.

No need to chase multiple suppliers.

No miscommunication between vendors.

We don’t pass your parts from factory to factory—we make everything ourselves.

No fragmented production.

No inconsistent standards.

Just one seamless process.

BESSER: One Supplier, All Solutions

We provide end-to-end services—from precision investment casting, heat treatment, CNC machining and surface treatment, to final assembly, ensuring every process is aligned, saving you time and effort.

You only need to provide us with your designs, and we take care of the rest.