3D Scanner Inspection

- Home

- 3D Scanner Inspection

What is 3D Scanner Inspection?

3D Scanning Inspection is a non-contact and efficient dimensional inspection method widely used in investment casting. Compared with traditional CMM, 3D scanning captures complete surface data, especially for complex and curved geometries. It projects laser or structured light onto the part to generate a point cloud, which is converted into a 3D model for comparing with CAD designs to detect dimensional deviations and surface defects.

This method is fast, accurate, and does not damage the part, making it ideal for inspecting precision castings with complex structures and reducing the limitations of CMM in freeform surface measurement.

Advantage of 3D Scanner Inspection

Fast Measurement Speed

Quickly captures the complete geometry of parts, significantly reducing inspection time.

Comprehensive Data Collection

Generates dense point cloud data covering the entire surface, including hidden and curved areas.

High Accuracy & Resolution

Offers detailed dimensional information, suitable for quality-critical components.

Non-Contact & Non-Destructive

Avoid any physical contact, making it ideal for delicate or soft surfaces.

Strong Adaptability

Effective for complex shapes, freeform surfaces, and various materials.

Visualized Analysis

Scanned data can be rendered as 3D models for intuitive comparison with CAD or reference data.

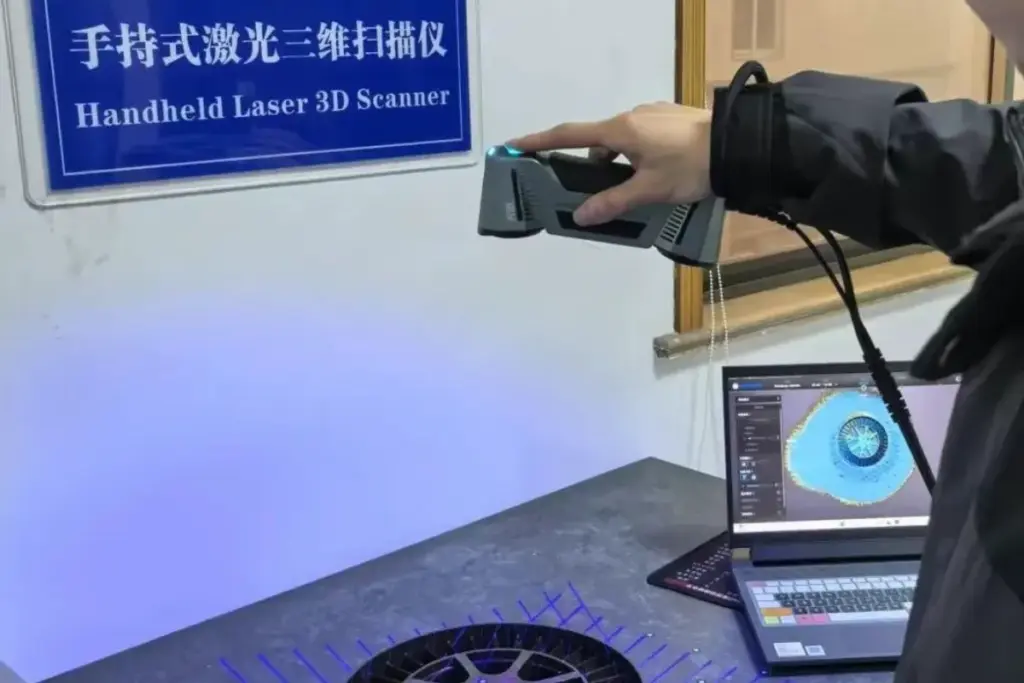

3D Scanner Inspection in Besser Foundry

At Besser, we deliver high-precision investment castings that help customers reduce welding and machining costs. To meet growing quality demands, we’ve integrated laser 3D scanner into our inspection process. Compared to traditional CMMs, 3D scanning is faster and captures full surface data—ideal for the complex shapes and curved surfaces typical of precision castings. This ensures reliable, accurate results for every part.

Partner with Besser for your next casting project and benefit from precision casting backed by cutting-edge inspection technology.