Silica Sol Investment Casting

- Home

- Silica Sol Investment Casting

What is Silica Sol Investment Casting?

Why Use Silica Sol Investment Casting?

Key Features

- Complex geometries achievable

- Ra 3.2-6.3μm as-cast finish

- Low-cost molds

- Micro-feature precision: Thin walls, small holes, sharp details

- Minimal post-processing requirements

- Wide material compatibility

- No harmful alkaline components or irritating odors

Our Casting Strengths

Technical Specifications

| Parameter | Silica Sol Casting |

|---|---|

| Weight Range | 10g - 280kg per casting |

| Surface Finish | Ra 3.2-6.3μm as-cast |

| Wall Thickness | 0.5mm (vacuum casting); 1.5mm (non-vacuum casting) |

| Size Limit | 1000*800*800mm |

| Dimension Tolerance | ±0.1mm, CT4-CT6 |

Need Help with Your Project?

— Our Products—

Typical Casting Products for

Diverse Industries

Water Valve

Material

Stainless Steel, Carbon Steel and Low Carbon Steel

Industry

Valve & Pump

Wrench

Material

Stainless Steel, Carbon Steel and Low Carbon Steel

Industry

Hardware

Pump

Material

Stainless Steel, Carbon Steel and Low Carbon Steel

Industry

Valve & Pump

Valve

Material

Stainless Steel, Carbon Steel and Low Carbon Steel

Industry

Valve & Pump

Impeller

Material

Stainless Steel, High-temperature Steel, and Nickel-based Steel

Industry

Automotive

Gas Valve

Material

Stainless Steel, Carbon Steel and Low Carbon Steel

Industry

Valve & Pump

— Better Quality, Lower Costs—

Taking Quality Seriously: Our In-House Testing Equipment

More Than Just Casting:

Our Full-Service Capabilities

Complete Heat Treatment

- Solution treatment

- Quenching and tempering

- Carburizing treatment

- Nitriding and nitrogen penetration

- Alloy penetration treatment

Advanced CNC Machining

- 3-axis and 4-axis machining centers

- Maximum workpiece dimensions: 800×800×600mm

- Precision tolerance capability: 0.01mm

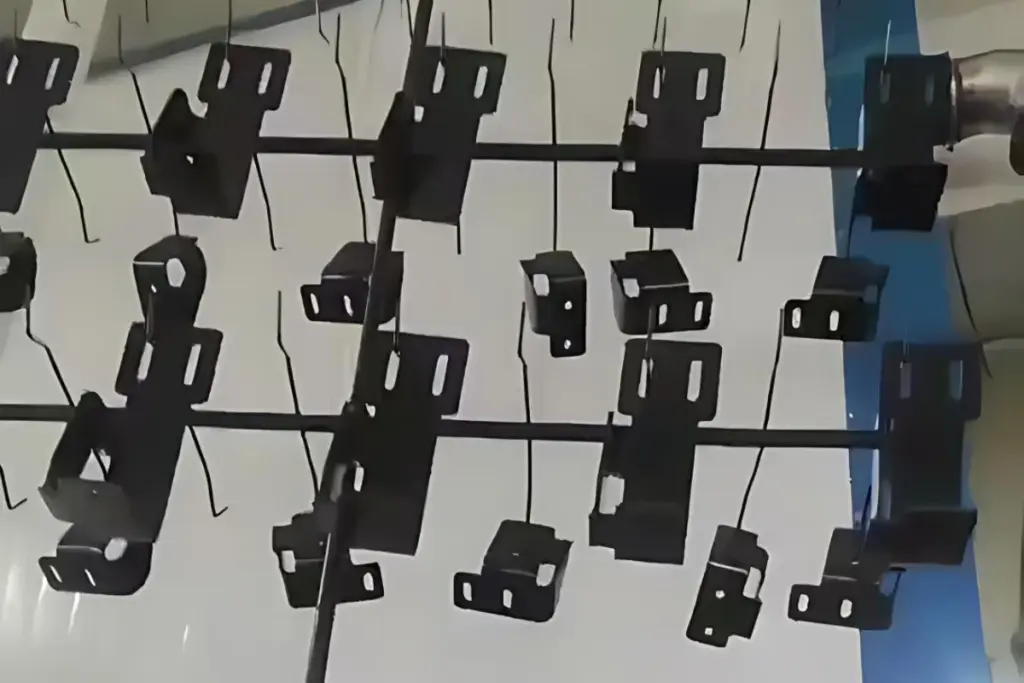

Superior Surface Finishing

We ensure your parts look good and perform well with 16 different surface finishing options. Our treatments include shot blasting, sand blasting, electrolytic polishing, acid cleaning, passivation, vibratory finishing, mirror polishing, wire drawing, painting, powder coating, zinc plating, dacromet coating, electrophoretic blackening, phosphating blackening, zinc-nickel plating, and chrome plating. Trust us for delivering one-stop solutions for all surface treatment needs.

Integrated Assembly Services

- Component assembly

- Testing of functional assemblies

- Comprehensive packaging for assembled components