32000㎡ Factory

- Home

- 32000㎡ Factory

Globally Certified Investment Casting Factory

BESSER is a foundry focused on silica sol investment casting and vacuum investment casting, equipped with a full production system covering key processes such as wax making, shell making, casting, heat treatment, machining, and surface treatment.

Supported by local government initiatives, we have been honored as a Three-Star Green Factory, recognized as the Ningbo Enterprise Technology R&D Center, and certified as a Digitized Smart Factory, reflecting our commitment to sustainability, innovation, and intelligent manufacturing. Trust us as a reliable and trusted long-term supply chain partner.

Factory Area

0

㎡

Skilled Workers

0

+

Production Workshops

0

Annually Capacity

0

tons

Caring for Our People and Environment

Operator Safety First

Clean, Healthy Workshops

Ongoing Green Investment

Operator Safety First

Protecting Every Worker

We provide full safety equipment for all frontline staff, including gloves, goggles, masks, and steel-toed shoes. Every workstation is designed for safe operation, with clear signage and load-handling protocols to prevent injuries.

Clean, Healthy Workshops

A Better Work Environment

Our workshops are equipped with ventilation systems and basic dust control facilities to ensure clean air and safe working conditions. Regular training and routine inspections help maintain a healthy, efficient production environment.

Ongoing Green Investment

Investing in a Greener Future

We have actively invested and upgraded our workshops with new dust extraction systems, air filtration units, and other eco-friendly equipment to improve air quality and reduce emissions. Our goal is to create a cleaner, quieter, and safer space—for both our people and the planet.

Our Production Capabilities

2 Automated

Shell-making Lines

Capable of completing 6-7 shell layers in 36 hours—5 times more efficient than the industry average—significantly shortening production cycles and enabling batch deliveries in as fast as 30 days.

14 CNC Machining Centers

Featuring 14 advanced CNC machining centers, capable of processing parts up to 800*800*600mm in size with precision as high as 0.01mm.

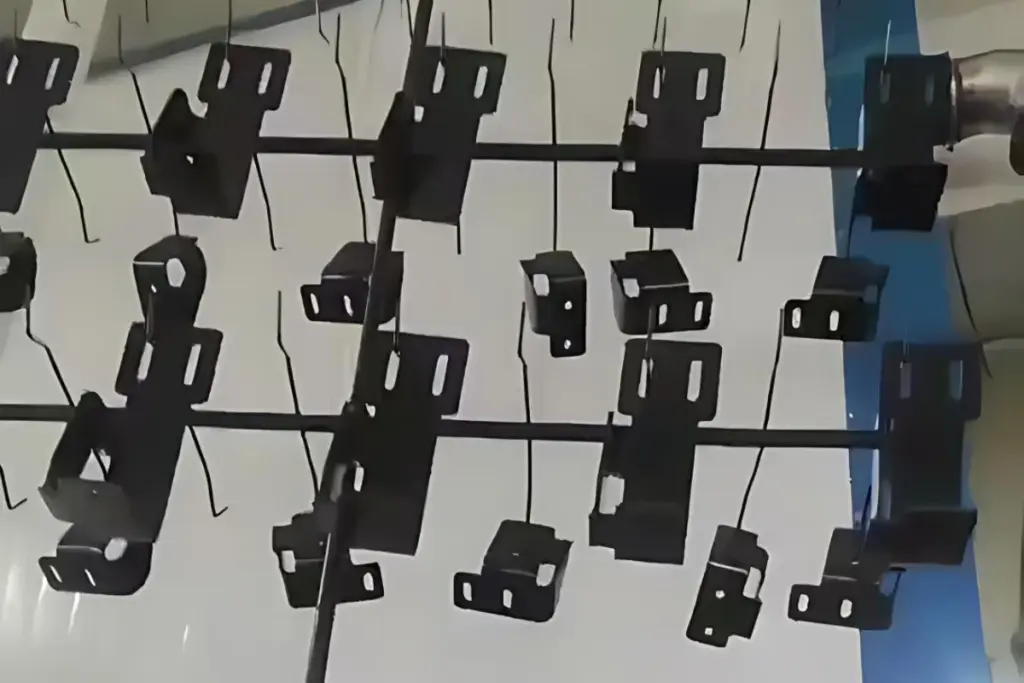

16+ Kinds of Surface Treatment

We master over 16 processes, including shot blasting, painting, electroplating, and more, offering a one-stop, efficient solution for all surface treatment needs.

Comprehensive Heat Treatment

BESSER offers a range of heat treatment processes, including solution treatment, quenching and tempering, carburizing, and nitriding, to optimize material properties.

Flexible Manufacturing Support

We can cast products ranging from 20g to 280kg, covering 200+ materials. With 4,800+ complex castings developed, we adjust alloy element ratios to meet your specific requirements.

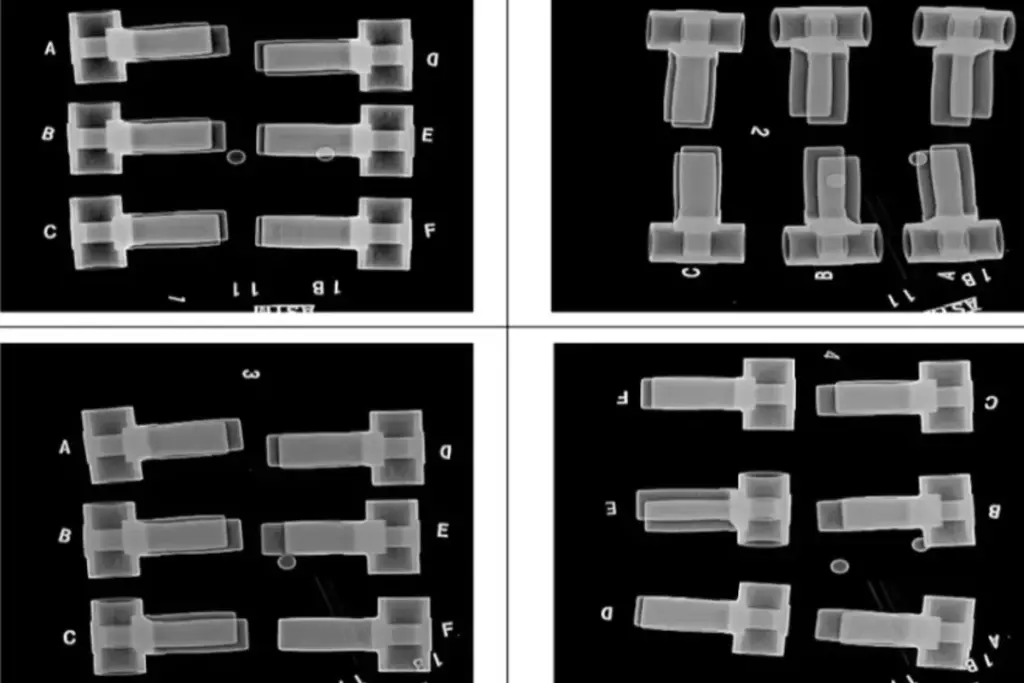

High-Standard Quality Inspection

We utilize advanced quality inspection tools like spectrometers, CMMs, and tensile testers—along with non-destructive testing methods such as magnetic particle, X-ray, and ultrasonic inspection to ensure material integrity, mechanical performance, and defect-free castings.

Precision Process Control

We continuously optimize internal production management and meticulously control each process, delivering the best surface finish (Ra 3.2) and precision (CT4-CT6), creating components that are visually inspectable by end users.

Our Highly-equipped Workshops

Our production process strictly adheres to the 5S management system, covering 8 workshops: wax molding, shell making, casting, sandblasting and shot blasting, cutting and grinding, finishing and inspection, reshaping, and CNC machining.